24

2018

-

08

The strategic value of China's modern coal chemical industry appears

分(fēn)类:

Industry News

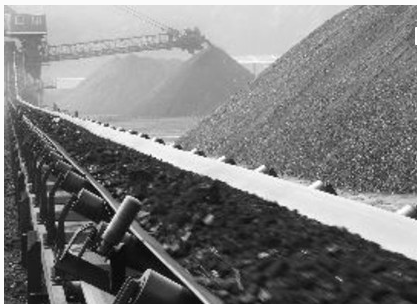

A recent interview in Ordos, Mongolia, in the National Modern Coal Chemical Industry Demonstration Zone, learned that after years of hard work, China’s modern coal chemical technology has become more mature, successfully turning coal into various chemicals such as oil, natural gas, olefins, and ethylene glycol. The Rubik's Cube, a way to replace oil and coal for clean and efficient use, is showing its strategic value.

Technological Leap Development

In Ordos City, the technology for producing diesel, naphtha and other oils and natural gas, methanol, olefins (ethylene, propylene and other materials), ethylene glycol and other chemicals from coal is now mature. Some business leaders and experts said that modern coal chemical technology is advancing by leaps and bounds, and new technological breakthroughs and projects are put into production almost every year.

Ordos City has the world's first and currently the only industrial production line for direct coal liquefaction to oil. It was built by Shenhua Group with an investment of over 10 billion yuan, and it has been officially put into commercial operation in 2011. Has attracted much attention at home and abroad.

Hu Qingbin, deputy chief engineer of Shenhua Ordos Coal-to-Liquid Branch, said that in the new century, Shenhua Group has concentrated on research and development of coal-to-liquid and other clean coal utilization technologies, and independently developed a complete set of technologies and catalysts for direct liquefaction of million-ton coal. By the end of 2017, the company had obtained 108 invention patents for direct coal liquefaction technology, and its core technology had been granted patents in 9 countries and regions including the United States, Russia, and the European Union.

At present, the construction plan of the second and third production lines of the project is in progress.

Modern coal chemical technologies, such as coal-to-natural gas and coal-to-olefins, have also been advancing continuously.

Located in Yijinhuoluo Banner, Ordos City, Huineng's 2 billion cubic meters/year coal-to-natural gas project is the second coal-to-natural gas demonstration project approved by China. Since 2015, the first phase with an annual output of 400 million cubic meters The project has achieved safety, stability, long period, full load and operation. In May this year, the second phase of the project with an annual output of 1.6 billion cubic meters has also begun construction.

In addition to substituting petrochemical products, the technology for producing new materials such as graphene and carbon fiber from coal has also continuously made new breakthroughs.

Since 2013, ENN Group has developed a technology for extracting graphene from low-calorific value coal. The first phase of the 1,000-ton graphene production project started construction in Dalate Banner, Ordos City in March this year. Qu Bo, general manager of the project, said that 3 tons of low-calorific value coal can extract 1 ton of graphene powder. The first phase of the project is expected to be put into operation in August this year, which will fill the technological gap in China in related fields.

After two years of pilot trials, Elcometer (Inner Mongolia) Coal Chemical Technology Co., Ltd. has successfully developed technologies for extracting carbon fiber and super activated carbon materials from high-temperature coal tar. The first phase of the production line with an annual output of 10,000 tons was in Ordos City in April this year. Zhungeerqi started construction and plans to start production in November this year.

Industrial scale growth

The reporter's survey found that, driven by national-level demonstration projects, in the past few years, modern coal chemical industries such as coal-to-liquid, coal-to-natural gas, and coal-to-olefins have grown in scale, showing a trend of large-scale, chained, and clustered development.

At the end of last year, the Zhongtian Hechuang Coal Deep Processing National Demonstration Project in Wushen Banner, Ordos City was fully put into operation. The project has a total investment of more than 50 billion yuan, which can transform 8 million tons of coal each year, and has a designed annual output of 3.6 million tons of methanol and 1.37 million. Tons of olefins, it is currently China's largest coal-chemical integration project.

Inner Mongolia Yitai Group is one of the first domestic coal companies to enter the coal-to-liquid field. Since 2002, Yitai Group has jointly established Zhongke Synthetic Oil Technology Co., Ltd. in conjunction with Chinese Academy of Sciences, Shenhua Group, and Lu'an Group to develop a complete set of coal indirect liquefaction technology and high-efficiency catalysts. The 160,000 tons/year coal indirect oil production industrialization Since the successful trial production in 2009, the demonstration project has been successfully operated for 9 years, and the annual production capacity of the demonstration project has been increased to 200,000 tons after technological upgrading in recent years.

Beijing Enterprises Group’s 4 billion cubic meters/year coal-to-natural gas project, Jiutai’s 600,000 tons/year methanol-to-olefins continuation project, ENN’s 200,000 tons/year stable light hydrocarbon project... As each project starts construction and goes into production, At the end of last year, Ordos City had built a modern coal chemical production capacity of more than 10 million tons.

The industry is also developing in a cluster. Since the construction of the Yitai 1.2 million tons/year fine chemical project in Hangjin Banner, 11 upstream and downstream supporting enterprises have successively attracted to settle around the project, which can produce dozens of chemical products such as high melting point synthetic wax, liquid paraffin, and stable light hydrocarbons. Products have formed an ecological industrial chain supporting upstream and downstream.

With the commissioning or construction of coal-to-liquid and coal-to-natural gas projects in Inner Mongolia, Ningxia, Shaanxi, Xinjiang and other places, China’s modern coal chemical industry has begun to take shape, and its products are also expanding into synthetic materials such as fiber, resin, and rubber. , End product extension.

Strategic value appears

Li Yongwang, general manager of China Synthetic Oil Technology Co., Ltd. and a researcher at the Shanxi Institute of Coal Chemistry of the Chinese Academy of Sciences, said that China’s resource endowment is rich in coal, short in oil, and low in gas. The development of a modern coal chemical industry is of great significance to the promotion of petroleum substitution and clean coal utilization. . With the expansion of industrial scale and technological improvement, the market competitiveness of modern coal chemical industry has been comparable to that of petrochemical industry, and its strategic value in replacing petroleum and the clean and efficient use of coal has become increasingly apparent.

According to Liu Jianqiang, general manager of Huineng Company, the LNG produced by the company has a purity of 99.7%, which is a clean energy source and is currently mainly used for heavy trucks and heating fuels.

With the improvement of technology, the cost of coal-to-liquid has been continuously reduced. Zhang Donghai, chairman of Yitai Group, gave an example of a 160,000 tons/year coal indirect liquefaction industrial demonstration project. Initially, 1 ton of catalyst can produce more than 500 tons of oil. Now it can produce more than 1,500 tons of oil. Consumption has been reduced from the originally designed 13 tons to 6 tons, and the comprehensive coal consumption has been reduced from 5.54 tons to 5.2 tons.

With reference to international crude oil prices, the demonstration project can be profitable when crude oil prices are higher than US$50. Due to the recent improvement in catalyst efficiency, the next step will be to further reduce the cost through large-scale gasifiers and other key equipment and technical upgrades.

Hu Qingbin, deputy chief engineer of Shenhua Ordos Coal-to-Liquid Branch, said that at present, the combined coal consumption of the first million-ton coal-to-liquid production line per ton of oil products is 3.5 tons, of which fuel coal is about 1 ton, and the price of crude oil is 55- A breakeven can be achieved when it is between $60. After the second and third production lines are completed, the oil recovery rate will increase by nearly 10%, and the profit and loss point will also drop below US$50/barrel.

In particular, the special coal-based oil product developed by Shenhua Ordos Coal-to-Liquid Branch can be used for both military and civilian purposes. For example, the ground equipment developed by the company has a low freezing point for general-purpose diesel fuel. It successfully conducted an extremely cold test at Zhongshan Station in Antarctica. It is suitable for global use, with stable quality and suitable for combat readiness storage; coal-based aviation jet fuel has entered trial production and application In the test phase, in February this year, coal-based aerospace kerosene was successfully tested on China’s new heavy-duty rocket engines, and coal-based special oil products such as coal-based warship oil are also under development. The development of related coal-based special oil products is of great significance to safeguarding national energy security.

In the past, petroleum was mainly used to produce olefin products in the country. The breakthrough of coal-to-olefin technology is of great significance to alleviating China's oil supply pressure.

Entrepreneurs said that with the maturity of modern coal chemical technology and the expansion of industrial scale, indicators such as coal consumption, water consumption, production cost, and unit capacity investment will have room for continued reduction, and energy conversion efficiency and product quality will also be further improved.

This article is reproduced from the Economic Information Daily

相关新(xīn)闻